Scientists in Hong Kong have developed new technology that enables polyester to be harvested from unwanted textiles and recycled into new clothes.

To continue reading, subscribe to Eco‑Business.

There's something for everyone. We offer a range of subscription plans.

- Access our stories and receive our Insights Weekly newsletter with the free EB Member plan.

- Unlock unlimited access to our content and archive with EB Circle.

- Publish your content with EB Premium.

The technology was invented by the Hong Kong Research Institute of Textiles and Apparel (HKRITA), and currently works for cotton-polyester blended fabrics, the institute announced last month.

Using a HKRITA-patented chemical solution, cotton is broken down into cellulose particles in a process that combines heat and water, and separated from the fabric.

The polyester fibres can be made into new garments straightaway with no loss in quality, which is why this new technology is being dubbed fibre-to-fibre recycling, Dr Gloria Yao, project development director of HKRITA and the lead researcher for this technology, said in an interview with Eco-Business.

“Compared to the production of virgin polyester, this method consumes 70 per cent less energy,” she added. HKRITA’s new methodology requires limited manpower, simple equipment that textile recycling companies may already own, and the water used in the process can be recycled.

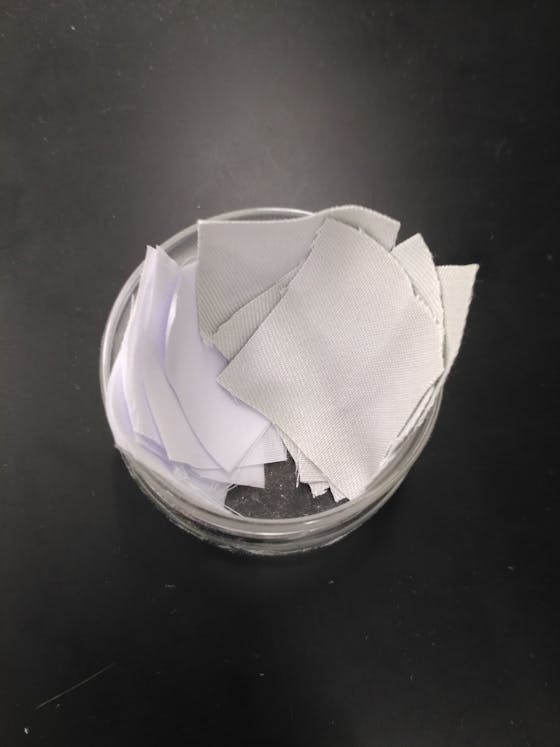

Pieces of fabric made froma blend of polyester and cotton, before treatment

The project is part of HKRITA’s four-year partnership with the non-profit H&M Foundation that began in 2016. Called the Closed-Loop Apparel Recycling Eco-System Program, it aims to find at least one technology to recycle clothes from blended textiles.

Erik Bang, innovation lead at the H&M Foundation, said the project team is working on a pilot plant slated to be operational within the next 12 months. “Our goal is to have the technology ready for the market by 2020.”

Once ready, the technology will be made available to companies through licensing, the terms of which have yet to be decided by HKRITA, which will own the licence.

HKRITA’s fibre-to-fibre method currently only works to repurpose polyester—a petroleum-based fibre found in most apparel—and further work is needed before it can recover other materials, said HKRITA’s Yao.

The research institute is also planning to study how cotton cellulose byproduct can be re-made into fibres and turned into clothing, she shared.

Image: Atlas; Data: Tecnon Orbichem

Polyester has been a pivotal part of the clothing industry since its invention in the mid-20th century, and is now the dominant fibre. Made from petroleum-based chemicals, about 65 per cent of polyester produced globally goes into textile production, and the rest into the common polyethylene terephthalate (PET) bottle that beverages are sold in.

The global fashion industry has faced increasing pressure over its environmental and social impacts. From toxic tanneries in India to labour rights violations in Uzbekistan, consumers are paying attention to how brands are—or are not—cleaning up their operations.

While brands such as Uniqlo and H&M have started garment take back programmes, only a fraction of the collected clothing can be recycled.

For instance, through an external company it has engaged to handle the garments, H&M sends about half of its collected clothing for rewear and 30 per cent to be recycled. “Within recycling, downcycling clothing to produce insulation materials or fillings forms the largest part, and a smaller part today can be upcycled into fibre,” said Ulrica Bogh-Lind, press officer for H&M. A part of this “becomes energy” through waste-to-energy incineration.

“Blended fabrics such as cotton and polyester make up the majority of textiles in the world today, but they are impossible to recycle as there is no technology to separate the materials,” said Bang.

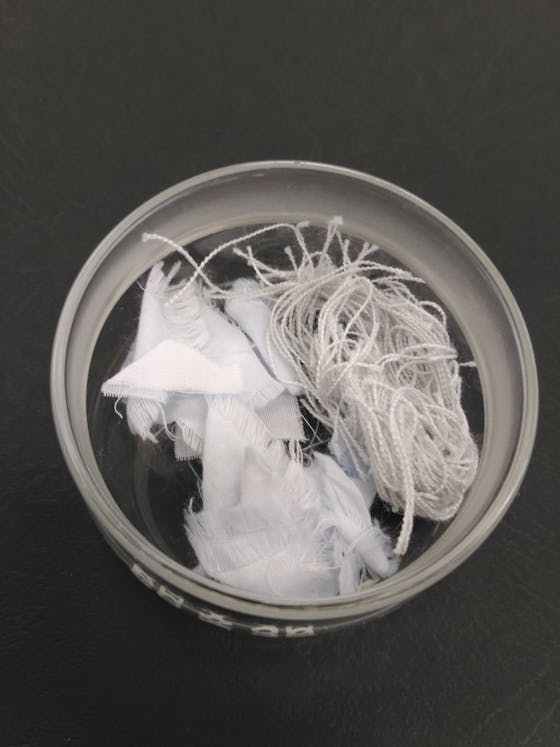

Polyester fibres extracted from the earlier fabric samples through HKRITA’s recycling technology. Image: HKRITA

Existing textile recycling methods mechanically shred textiles into fibres, therefore reducing the length and quality of the fibres. They have to be combined with virgin fibres to make new garments.

More brands today, from adidas to H&M to Patagonia, are upcycling PET bottles as raw materials for their products, although this material cannot be recycled easily due to the same technological limitations.

Bang commented: “If this fibre-to-fibre project succeeds, the fashion industry could meet the growing global demand for clothes without having to rely on virgin materials—saving precious natural resources and significantly reducing its impact on the climate and natural ecosystems.”

Furthermore, critics have pointed out that shorter fashion cycles thanks to fast fashion labels like Zara, Mango, Forever 21 and H&M are encouraging overconsumption even though the industry has not figured out how to properly handle textile waste.

But Bogh-Lind told Eco-Business that H&M does not consider itself a fast fashion company and does not encourage a throw-away attitude. “It’s important that customers value and take care of the clothes they buy, and that companies take responsibility for the products they offer—not only at the production and selling stages, but also when the customer doesn’t want the product any more.”

“A circular approach to how fashion is the key solution to the negative impacts of consumption,” she added.