Ammonia, a colourless fuel that emits no carbon dioxide when burned, is fast gaining favour in the global shipping industry. The sector, facing pressures to decarbonise, is in urgent need of cleaner fuels to power its freighters and tankers, and ammonia seems like an attractive option.

To continue reading, subscribe to Eco‑Business.

There's something for everyone. We offer a range of subscription plans.

- Access our stories and receive our Insights Weekly newsletter with the free EB Member plan.

- Unlock unlimited access to our content and archive with EB Circle.

- Publish your content with EB Premium.

No vessels of any size today, however, are equipped to use the fuel. The supply of renewable ammonia produced using carbon-neutral methods is also virtually nonexistent, though that does not mean meaningful action cannot be taken now to prepare for its eventual use to fuel a ship, said the chief executive of Singapore-based Global Centre for Maritime Decarbonisation (GCMD), Lynn Loo.

“We know the first ammonia ship engine is not going to be built until 2024. The first ships that run on ammonia fuel will not be available probably until only a year after that,” said Loo. “But we are not going to sit around and twiddle our thumbs.”

Formerly the director of the Andlinger Centre at America’s Princeton University, Loo is on leave from the university to lead GCMD’s efforts at maritime decarbonisation. The Malaysian-born chemical engineer, once a stranger to the sector, has become a recognisable face in the industry, as she has been engaging key shipping players — a total of 150 stakeholders — since the centre was set up as a non-profit in August last year, to understand its pain points.

On GCMD’s ammonia bunkering safety study, led by ship classification society DNV, Loo told Eco-Business in an interview ahead of Singapore Maritime Week that this was proposed after realising that the safe handling of ammonia is a gap that needs to be closed. The study, likely to be completed by the end of the year, will further scope the guidelines for a pilot, to be conducted in Singapore.

“Even without an actual ship that we can burn ammonia on, we will conduct the pilot on proxy assets. The proxy ship could be one that already carries ammonia as cargo, and we could have a truck-to-ship type of configuration. The goal is to accelerate and speed up the process,” said Loo.

“The use of ammonia as an alternative fuel depends on the availability of green ammonia, and we fully recognise that there may not be enough green ammonia for us to do a meaningful pilot then, in which case we are going to use grey ammonia first,” she said.

This can-do spirit guides the work of GCMD, which takes a multi-fuel approach to shipping decarbonisation. This week, it signs on four new partners, including BP and Chevron, two energy majors. Next on its horizon are carbon capture trials on board vessels, revealed Loo.

GCMD’s other two new partners are the International Chamber of Shipping (ICS) and Boston Consulting Group (BCG). The four partners bring with them a combined S$25 million (US$18.4 million) through cash and in-kind contributions. The centre was set up with a S$120 million (US$88.1 million) fund from Singapore’s Maritime Port Authority (MPA) and six founding partners namely BHP, BW Group, Eastern Pacific Shipping, Foundation Det Norske Veritas, Ocean Network Express and Sembcorp Marine.

Maritime shipping contributes nearly 3 per cent of annual carbon dioxide emissions, according to the International Maritime Organisation (IMO), the United Nations body that regulates the industry. In 2018, IMO delegates agreed to reduce shipping emissions by 50 per cent from 2008 by 2050. Meeting that target will require swift and widespread development of diesel-fuel alternatives and new designs for vessels.

This week, one of the world’s leading energy houses BP joined GCMD as a strategic partner. From left: Andreas Sohmen-Pao, chairman of GCMD’s board; Professor Lynn Loo, chief executive officer, GCMD; Federica Berra, SVP, gas & low carbon energy, BP; Eugene Leong, BP Singapore president and CEO, trading & shipping Asia-Pacific & Middle East. Image: BP

“Our direct emissions is the oil producer’s indirect emissions, or Scope 3 emissions, so we are in this together. Signing the agreements with the two oil and gas majors this week is a big deal as it speaks to the upstream,” said Loo.

In this interview, Loo shares her thoughts about the complex choices that the shipping industry faces, and why it is possible to move faster if efforts are coordinated.

How meaningful is it that the GCMD is modelled as a private-public investment initiative? You have been upfront about how the centre has a “war chest of funds” to work with. Does GCMD’s model lend momentum to the financing of its projects, especially since shipping decarbonisation is extraordinarily expensive?

When we talk about shipping decarbonisation and its required financing, the numbers are huge and could be anywhere between US$2-3 trillion. In fact, 80 per cent of it needs to be spent on land infrastructure. So I think we need to put everything in perspective. While we have a war chest, our war chest is small in comparison to what is needed as a whole.

The philosophy of GCMD is to take action, and fundamentally we are about pilots and trials. Financing is one of the hurdles we face. The regulatory hurdles are also huge, because ultimately for the pilots, we have to put things into the water, we are producing emissions and we have to consider the safety of the people. Having Singapore’s MPA as a partner gives us early access to the authorities and opens doors for us to the other agencies that need to be involved. The war chest that we have provides capital for the pilots.

The whole idea is to do things faster, because we want to accelerate the process of decarbonisation. There are two outcomes: we either fail fast and learn fast, or succeed and lower the barriers for the industry to adopt the solutions.

“

Singapore is a strategic place to be in. It is thinking about pricing carbon and implementing market-based measures, and that helps financially to internalise the cost of polluting our environment. When you have that, it tilts the balance and lowers the barrier for adopting incumbent technologies.

The shipping industry is betting big on ammonia, yet the fuel comes with associated risks. Can you tell us more about the ammonia bunkering study? What is the timeline for operationalising safe bunkering?

The biggest thing about ammonia is its toxicity, but as an engineer, I believe that we can come up with solutions and I take inspiration from other sectors. For example, chlorine gas is super toxic but the chemical industry figured out how to handle it right and now it is the basic component in many products. Silane is toxic too, and the semiconductor industry figured out how to handle it and that has revolutionised the industry. There are precedents of toxic chemicals being used safely.

We have mapped out the supply chain and present gaps for ammonia use, and we are starting with a safety study simply because the safety needs have to be articulated. What are the conditions under which we can bunker ammonia safely? How do we train people to do it? Ammonia is now being moved around as cargo, but as a bunker fuel, the transfer frequency is going to be much higher and the procedure is carried out near densely-populated areas, so we need to get safety right down to the configuration of the ship.

You need to figure out where the storage terminals are going to be, and the study is going to identify two sites in Singapore where we can conduct the pilot. It will likely be completed before the end of the year, and it is going to provide the basis, some sort of a regulatory sandbox, for us to conduct an actual pilot — to demonstrate that we can move the ammonia molecule safely from storage facility onto a vessel, or from a truck to a bunkering barge then to a ship.

What else is on the horizon for GCMD?

The long-term solutions are what is going to get the sector to net-zero and the ammonia bunkering safety study goes a long way towards that. Meanwhile, we are also thinking about what the industry can do in the near- and medium- term. We should focus on improving energy efficiency and reducing fuel consumption now, so firstly, we are looking at wind-assisted propulsion technologies, for example. That will decrease carbon emissions, depending on weather patterns, by about 10 per cent. It’s not a 100 per cent reduction, but the figure is not small.

Then we have to ask ourselves what are the fuels available today, besides diesel and heavy fuel oil? What we have are liquefied natural gas (LNG) and biofuels and they are not zero carbon. They can, however, be lower carbon if the slip and leakage are managed responsibly.

We are also looking at shipboard carbon capture trials. Cargo space on board vessels will always be at a premium, so the challenge is: to what extent are ship owners willing to give up space to store carbon dioxide, especially if you generate about three tonnes of it for every tonne of fuel you burn. There is an economic balance there. We are going to try putting a scrubber on board, for example, have the vessel sail and capture the CO2 and most importantly, trial the offloading process. That is something that has not been piloted.

If you were to put on a critical lens to evaluate where the shipping industry is heading with regards to decarbonisation, what would you say are some of the roadblocks?

The momentum for decarbonisation is fast, but the landscape is very complex. It is very confusing for ship owners and ship charters because there are mixed messages out there. There are memorandums of understanding that are being signed, with various stakeholders promising delivery of large amounts of green hydrogen, with no timeline pegged to it. It elicits a sort of reaction that maritime decarbonisation is just around the corner — but it is not.

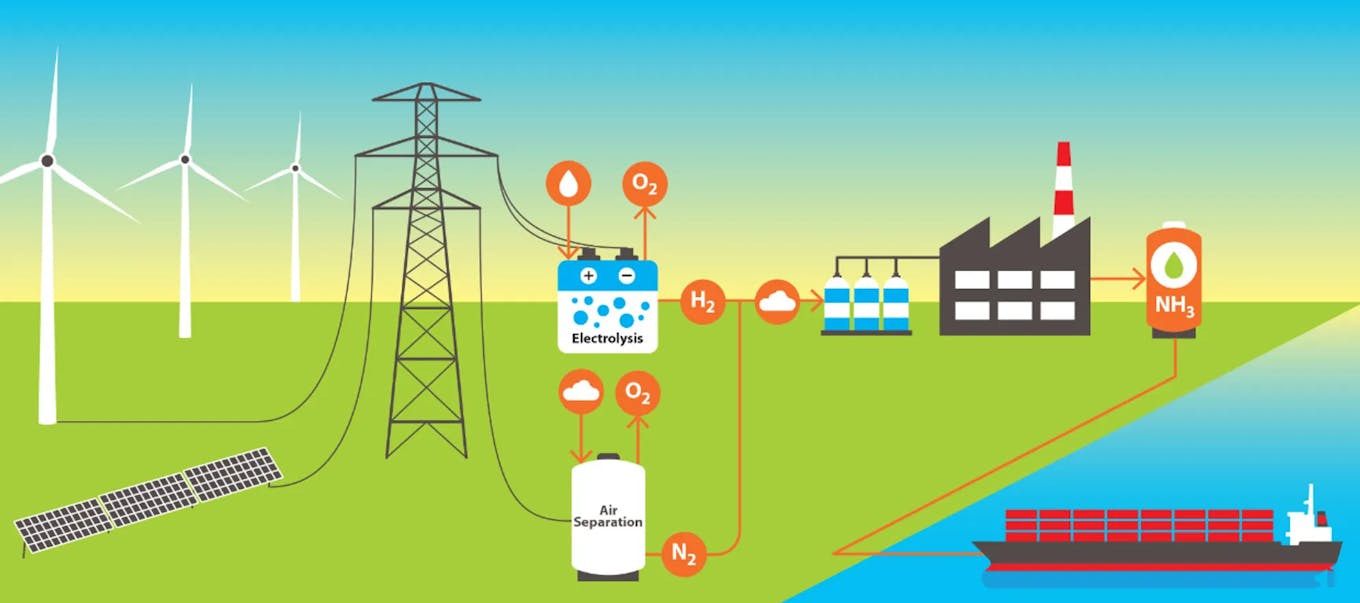

The traditional Haber-Bosch process is used to produce virtually all of the world’s ammonia, but it is energy and carbon intensive. To decarbonize the ammonia-making process, electricity from renewable sources, such as wind and solar power, is used to electrolyse water, yielding hydrogen (as well as oxygen). The hydrogen is then reacted with the nitrogen to produce ammonia, NH 3. Image: IEEE Spectrum

I think it is important to have a grounded conversation and understand the timeline properly. The current energy infrastructure took more than a century to build. We are now talking about dismantling it and building a completely different one in less than 30 years. For example, green ammonia is not going to be available tomorrow because of upstream complexity. You need to have enough solar and wind projects to have the green electrons for producing ammonia, and even if that happens, the renewables have different end users, and only a fraction of it is used to make green hydrogen, and subsequently green ammonia. The Ukraine-Russian conflict is not helpful in that respect, because the global supply chain is going to slow down the build up of solar and wind projects. It will have a ripple effect across all sectors. We need to untangle some of the complexities and contextualise the problem correctly.

What was your first foray into sustainability? You took leave from Princeton University to lead GCMD’s efforts in maritime decarbonisation, could you tell us more about how that came about?

I was first interested in energy. My dad was a Shell employee and he would bring home these posters that would show how distillation columns worked and I was inspired and fascinated by these processes — where you put in the yucky black stuff and get kerosene at different grades and prices. As an undergraduate, I got interested in plastic and I did a lot of work trying to understand what gave various type of plastics their mechanical properties. [Loo later invented nanotransfer printing, a method of transferring nanoscale features onto organic electronics and plastic circuits.] I became more aware about sustainability from these experiences and started applying them to make new materials and new energy applications. It got me very interested in solar cells and taking up a role at the Andlinger Centre at Princeton later was my big jump into looking at energy systems. I realised that I could do all the research that I want in the lab, but if I want to make a real impact, I need to understand the complexity of energy systems.

In 2020, Princeton University embarked on the net-zero America project, which aims to inform policy and investment decisions around achieving net-zero emissions by 2050 in the United States. It struck me then that the discourse in the US was all about mitigation, and there was no room to talk about adaptation, yet I thought it could not be so black and white. Singapore struck me as the model place to learn about adaptation and building up resilience, because it is an island nation.

I came to Singapore with the intention of talking to people about these topics, then Covid-19 hit and I was stuck here. By chance, I was invited to be a part of an international advisory panel for maritime decarbonisation. I knew nothing about the sector and was hesitant, but they said they were looking for people with a broad energy systems perspective, so I agreed to join, becoming one of only two academics on the panel, alongside ship owners, ship charters, fuel producers and battery suppliers. We were focused on thinking about actions that we can take today. Everyone was not interested in just writing another report.

About a year ago, we made recommendations that were submitted to the Singapore government and they decided to endorse the idea of founding a maritime decarbonisation centre, and for it to be based in Singapore. I took up the leadership position when they approached me because I wanted to create a meaningful impact as an engineer, even if this is fundamentally different from my usual work.

Singapore is the world’s busiest container transhipment port, handling a record high of 37.5 million TEUs of container throughput in 2021. Image: CHUTTERSNAP / Unsplash

How does having the centre based in Singapore help its work?

Singapore is a strategic place to be in. It is thinking about pricing carbon and implementing market-based measures, and that helps financially to internalise the cost of polluting our environment. When you have that, it tilts the balance and lowers the barrier for adopting incumbent technologies. From a maritime perspective, it is the largest bunkering hub, the second largest cargo terminal and one of the largest transhipment ports in the world. There are many shipping companies that have their headquarters here and many ships are flagged here.

Being in Singapore also lends an Asia-Pacific lens to the work that we do. The region is unique as compared to Europe. It is essentially a big body of water with islands scattered in between and that makes it different when you think about shipping routes. Singapore is population dense and the ports are crowded with many ships. For the ammonia bunkering study, if we can demonstrate that we can do it safely in Singapore, where there are huge constraints and the rules are very stringent, then the safety guidelines are extensible elsewhere.

GCMD has been actively engaging different stakeholders at forums, such as at the Singapore Maritime Week. You will be participating in Ecosperity Week in June, to discuss the decarbonisation of transport and heavy industry. How do you approach the engagement of these partners?

Shipping contributes 3 per cent of global carbon emissions and the emissions are very difficult to abate. At the same time, the sector is responsible for transporting 80 to 90 per cent of global goods, so within the global supply chain, our Scope 1 emissions or emissions from our direct operations, is our customer’s Scope 3 emissions, or indirect emissions embedded in the value chain. It is the oil producer’s Scope 3 emissions too, so we are in this together, and collaboration becomes very important. It is the reason why we have been trying to bring energy producers into the conversations. Within the transport sector, collaborating with aviation is important too. They look very much like us, and our challenges and opportunities are alike. They also contribute about 3 per cent of global carbon emissions. We should avoid the duplication of efforts and share common infrastructure. We are open-minded about who we work with, as long as it speaks to decarbonisation.

This interview has been edited for clarity and brevity.