Consumers are demanding more transparency about where their clothes are produced and under what conditions. With the average supply chain for a merino sweater spanning 28,000 kilometres, fashion brands have the colossal task of tracing a product’s history from field to shelf in a bid to clean-up the sector’s spotty environmental, social and governance (ESG) record.

To continue reading, subscribe to Eco‑Business.

There's something for everyone. We offer a range of subscription plans.

- Access our stories and receive our Insights Weekly newsletter with the free EB Member plan.

- Unlock unlimited access to our content and archive with EB Circle.

- Publish your content with EB Premium.

In partnership with conservation group World Wide Fund for Nature (WWF), fashion label Stella McCartney and non-profit The Textile Exchange, the search giant has developed the Google Impact Fibre Explorer, that it says will enable companies to identify the biggest risks associated with more than 20 fibre types in their supply chains, including synthetics.

Despite sustainability pledges, the fashion industry is failing to tackle its hefty carbon and environmental footprint and is on a trajectory that will far-exceed the pathway to mitigate climate change to align with the United Nation’s goal of keeping global temperatures from rising above 1.5°C since pre-industrial times, according to research by McKinsey, a consultancy.

The fashion industry is one of the largest contributors to the global climate and ecological crisis — accounting for up to 8 per cent of global greenhouse gas emissions.

A large chunk of emissions could be avoided in its upstream operations with approximately 70 per cent of the industry’s greenhouse gas emissions stem from energy-intensive raw material production.

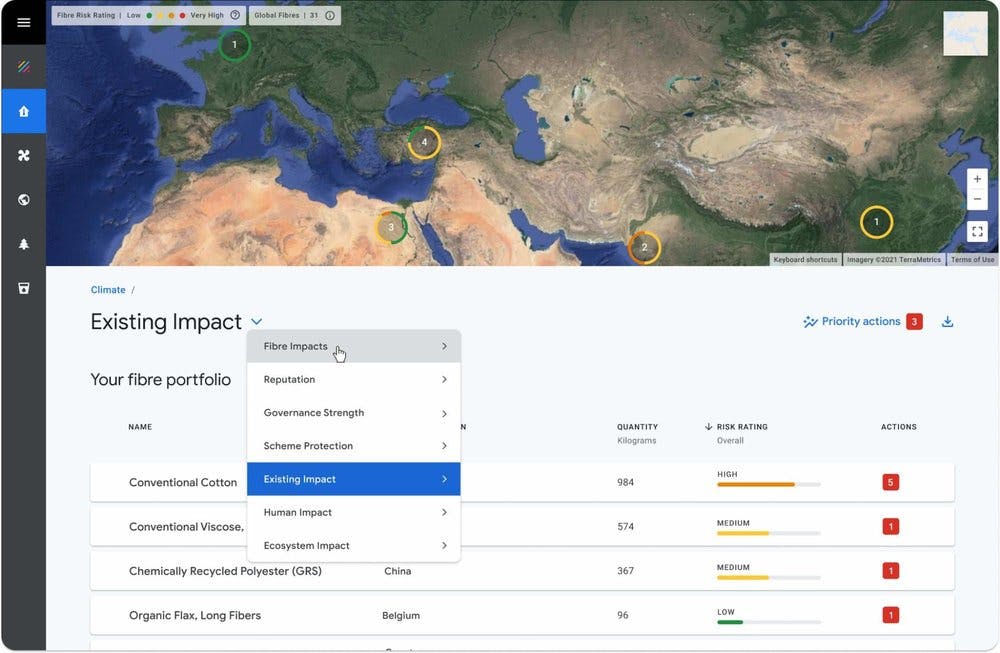

The Global Fibre Impact Explorer (GFIE) dashboard allows brands to upload their fibre portfolio data and get recommendations to reduce risk across key environmental categories. Image: The Keyword, Google

Environmental factors such as air pollution, biodiversity, climate and greenhouse gasses, forestry and water use are calculated to produce risk ratings. The tool will also provide brands with recommendations for targeted and regionally specific risk reduction activities including opportunities to work with farmers, producers and communities.

During a pilot phase, British fashion house Stella McCartney was able to identify cotton sources in Turkey that are facing water stress.

Brands such as Chanel, Nike and H&M are among the 130 companies that have pledged to halve their greenhouse gas emissions by 2030 under the renewed United Nations Fashion Charter announced last month during climate talks in Glasgow. Alongside updated commitments to cut emissions, the charter promises to reduce the environmental impact from the use of materials such as cotton, viscose, polyester, wool and leather.

The renewed agreement is more ambitious than a previous commitment in 2018 to cut emissions by a third. Nevertheless, the signatories represent a slither of the vast garment and footwear industry with fast-fashion brands such as BooHoo, Shein and ASOS notably missing from list.

The textiles sector also called for policy change to incentivise the use of “environmentally preferred” materials, such as organic cotton and recycled fibres earlier this month.

“

Consumers do not want to buy products made with forced labour…Without government regulations, many companies will continue to make choices based on profits not on rights.

Laura Murphy, professor of human rights and contemporary slavery, Helena Kennedy Centre for International Justice

Improved data mapping tools should help to shed light on fashion’s murky supply chains. Many brands do not have reliable information on their upstream suppliers beyond the manufacturers they deal with. Data from cotton farms and spinners are rarely available on paper, let alone a digital format. Blind-spots are perpetuating environmental and social problems that have dogged the industry for decades.

Cotton supply, in particular, has come under the spotlight. China’s northwestern Xinjiang region, which produces a fifth of the world’s cotton, is where the Chinese government has allegedly committed grave human-rights violations against the largely Muslim population of Uyghurs and other minorities.

A new report published on 17 November by Sheffield Hallam University in the United Kingdom analysed supply chain connections identified through shipping records to show how cotton from the Uyghur region circumvents supply standards and import bans to end up in consumer wardrobes around the world.

In the report, Laundering Cotton: How Xinjiang Cotton is Obscured in International Supply Chains, Professor Laura Murphy and co-authors identify more than 50 contract garment suppliers – in Indonesia, Sri Lanka, Bangladesh, Vietnam, India, Pakistan, Kenya, Ethiopia, China and Mexico – that use the Xinjiang fabric and yarn in the clothes they make for leading brands, “thus obscuring the provenance of the cotton.”

“The benefits of such an export strategy may be clear: the end buyer is no longer directly involved in buying Xinjiang cotton,” the report said. “International brands and wholesalers can buy from factories in third countries that have few visible ties with Uyghur region-based companies.”

The researchers identified over 100 international retailers downstream of Xinjiang cotton, Murphy told media on a call on Friday. These include Levi Strauss, Lululemon, H&M, Marks & Spencer and Uniqlo, according to the report.

“Consumers do not want to buy products made with forced labour,” Murphy told Eco-Business. “We need our governments to insist that companies trace their supply chains back to the raw materials and make those findings public. Without government regulations, many companies will continue to make choices based on profits not on rights.”