The Massachusetts Institute of Technology here today presented early results of research projects funded by Italian oil company Eni, including paper-thin solar cells, which could be used as window covers, and a paper-based material to collect oil spilled in water.

MIT showed prototypes of paper solar cells able to generate enough current to light a small LED display. A commercial solar paper device could be available in five years, said chemical engineering professor Karen Gleason, whose lab is doing the work.

“It’d be a matter of economics and investment on the time frame for large-scale commercialization,” she said. “If everything went great, I think five years is not unreasonable.”

Gleason envisions using cheap paper solar cells on blinds and shades or perhaps on the cover of a laptop. A blind could have a storage device integrated into it or be connected to home wiring, she said.

Paper cells can also be laminated into flexible, lightweight strips that could be attached quickly onto roofs by untrained people, reducing the cost of solar power, she said. The cells are made on ordinary tracing paper.

The trick behind the paper-thin solar cells is a layer-by-layer manufacturing process developed by Gleason’s lab, which can be adjusted for different purposes.

To make a cell, five layers of solid material are deposited onto a paper substrate. Each layer serves a different function, such as the active material that releases an electron when struck by light and the circuit that carries the current, she explained. Unlike many solar cell deposition processes, this one can be done at low temperatures.

It’s analogous to frost forming on a window where water vapor turns into a solid on a surface, Gleason said.

“We have an apparatus which allows us to bring together molecular and atomic species. They basically condense, sometimes they react. We repeat that five times and you up with a solar cell,” she said.

Right now, the efficiency of light-to-electricity conversion is very low, approaching 1 percent. The lab’s target is to get to 4 percent efficiency on paper and higher efficiency on different substrates, Gleason said. Commercial solar panels with silicon solar cells have an efficiency around 15 percent and higher.

The process uses organic materials and polymers, which are abundant and thus not expensive. “We want elements readily available in nature. It’s simple metals—nothing exotic,” she said.

Gleason imagines indoor applications for the solar cells because that is a niche not already served.

Hydrophobic nanowires

In another Eni-funded research area, MIT professors are using paper in a very different way: to soak up oil from water.

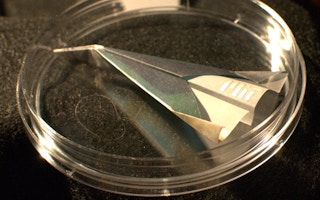

Professor Philip Gschwend presented an early prototype of a specially treated paper that researchers say could be deployed to remove oil and other chemicals, such as solvents, already dissolved in water.

For example, buoys lined with the material could be deployed near a tanker or oil well. The buoy would absorb spilled oil into a holding tank, which could then be pumped into an oil-carrying vessel. Gschwend said the technology could also be used to absorb underwater plumes, which happened in the Gulf of Mexico oil spill earlier this year.

To create the oil-absorbing material, researchers treated paper with water-repelling, or hydrophobic, nanomaterial. Gschwend showed a video of a proof of concept where a paper cone in a beaker of water and oil attracted oil droplets. The cone collected the oil without water seeping through as well.

Treating the paper is also a deposition process similar to how snack bags are coated on the inside with a separate material, he said. Development of working systems would require ensuring that buoys can withstand harsh outdoor conditions over time, he said, adding that it would take “years” rather than decades to make a commercial product.

Paolo Scaroni, the CEO of Eni, said that oil remediation is an urgent need in the oil drilling industry.

“The amount of oil spills in the world is much more than people think. Oil spills happen almost every day,” he said. “A tissue like this can have practical use immediately.”